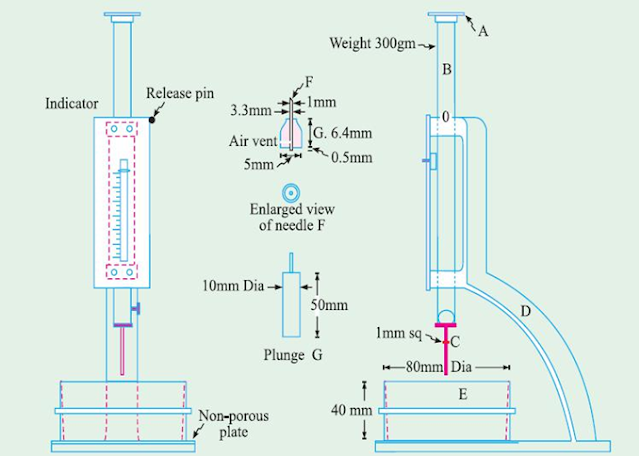

For finding out initial setting time, final setting time and soundness of cement, and strength a parameter known as standard consistency has to be used. The standard consistency of a cement paste is defined as that consistency which will permit a Vicat plunger having 10 mm diameter and 50 mm length to penetrate to a depth of 33-35 mm from the top of the mould.

Vicat apparatus conforming to IS : 5513-1976, Balance, Gauging Trowel, Stop Watch, etc.

2.Initially a cement sample of about 300 g is taken in a tray and is mixed with a known percentage of water by weight of cement, say starting from 26% and then it is increased by every 2% until the normal consistency is achieved.

3.Prepare a paste of 300 g of Cement with a weighed quantity of potable or distilled water, taking care that the time of gauging is not less than 3 minutes, nor more than 5 min, and the gauging shall be completed before any sign of setting occurs. The gauging time shall be counted from the time of adding water to the dry cement until commencing to fill the mould.

4.Fill the Vicat mould (E) with this paste, the mould resting upon a non-porous plate. After completely filling the mould, smoothen the surface of the paste, making it level with the top of the mould. The mould may be slightly shaken to expel the air.

5.Place the test block in the mould, together with the non-porous resting plate, under the rod bearing the plunger; lower the plunger gently to touch the surface of the test block, and quickly release, allowing it to sink into the paste. This operation shall be carried out immediately after filling the mould.

6.Prepare trial pastes with varying percentages of water and test as described above until the amount of water necessary for making up the standard consistency as defined in Step 1 is found.

Generally the normal consistency for OPC ranges from 26 to 33%.

Apparatus:

|

| Vicat apparatus |

Vicat apparatus conforming to IS : 5513-1976, Balance, Gauging Trowel, Stop Watch, etc.

Procedure:

1.The standard consistency of a cement paste is defined as that consistency which will permit the Vicat plunger to penetrate to a point 5 to 7 mm from the bottom of the Vicat mould2.Initially a cement sample of about 300 g is taken in a tray and is mixed with a known percentage of water by weight of cement, say starting from 26% and then it is increased by every 2% until the normal consistency is achieved.

3.Prepare a paste of 300 g of Cement with a weighed quantity of potable or distilled water, taking care that the time of gauging is not less than 3 minutes, nor more than 5 min, and the gauging shall be completed before any sign of setting occurs. The gauging time shall be counted from the time of adding water to the dry cement until commencing to fill the mould.

4.Fill the Vicat mould (E) with this paste, the mould resting upon a non-porous plate. After completely filling the mould, smoothen the surface of the paste, making it level with the top of the mould. The mould may be slightly shaken to expel the air.

5.Place the test block in the mould, together with the non-porous resting plate, under the rod bearing the plunger; lower the plunger gently to touch the surface of the test block, and quickly release, allowing it to sink into the paste. This operation shall be carried out immediately after filling the mould.

6.Prepare trial pastes with varying percentages of water and test as described above until the amount of water necessary for making up the standard consistency as defined in Step 1 is found.

Observation:

Express the amount of water as a percentage by mass of the dry cement to the first place of decimal.Result:

The normal consistency of a given sample of cement is _ _ _ _ %Conclusion:

Consistency refers to the relative mobility of a freshly mixed cement paste or mortar or its ability to flow. For a mortar the standard consistency is measured by flow table test.Generally the normal consistency for OPC ranges from 26 to 33%.

![[PDF] IS 456 2000 | Download Civil Engineering Code](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjl8mzhZI_smGwhJPipCx2TuxHldgAvnHrYfkud8mDJ1kF4Syd83-TNKsXjyY1BVxFrxZ1tt-fErpupgiF146wqOfPtGo8M9GWrnQX9b9TyA-YtjlNWnlwdk9LaMN_JJN8AGCU619UI6Uu_/w100/is-456-2000.JPG)

![[PDF] SP 16 :1980 Design Aids For Reinforced Concrete to IS : 456-1978](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEj3vWyWR9sVpY2Mcip5F3ttq_4jje6Et0mqiBug-q8n7kClvXle3KD0XtZBwYBtmYFfIekvQYIW9gFB5aqcri6KrHD4x2PalOyEWAXPkLNFfbXe8m9m8WvCLSEWok7vPivvYidB1tj8JjeX/w100/is-sp-16-1980.JPG)

![[PDF] Download IS 800 Code | Indian Standard Code for Steel](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjMmVdQd3q6sKYLbOG23DVJg2U_8IrdWJSfCcyA7gKs5NKVFBsi6dFPhGxoVctqzOHEIvJ6pqvQ6mpFMd5vV0U5IQHo-FETwRXTjbZ-Dok9CHxUJgePxHyFTHa2pNiWyW4mkYCJWOv_2IcP/w100/is-800-2007.JPG)

0 Comments