One of the model in which pavement material can fail is by crushing under compressive stress. A test is Standardized by IS:2386 part-IV and used to determine the crushing strength of aggregates. The aggregate crushing value provides a relative measure of resistance to crushing under gradually applied crushing load.

AIM

1) To determine the aggregate crushing value of coarse aggregates

2) To assess suitability of aggregates for use in different types of road pavement

PRINCIPLE

The aggregate crushing value gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load. Crushing value is a measure of the strength of the aggregate. The aggregates should therefore have minimum crushing value.

APPARATUS

The apparatus of the aggregate crushing value test as per IS: 2386 (Part IV) – 1963 consists of:

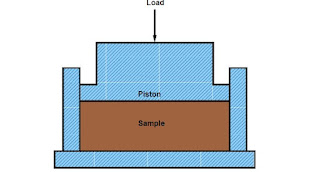

1) A 15cm diameter open ended steel cylinder with plunger and base plate, of the general form and dimensions as shown in Fig 1.

2) A straight metal tamping rod of circular cross-section 16mm diameter and 45 to 60

cm long, rounded at one end.

3) A balance of capacity 3k, readable and accurate up to 1 g.

4) IS Sieves of sizes 12.5,10 and 2.36 mm

5) A compression testing machine capable of applying a load of 40 tonnes and which can be operated to give a uniform rate of loading so that the maximum load is reached in

10 minutes. The machine may be used with or without a spherical seating

6) For measuring the sample, cylindrical metal measure of sufficient rigidity to retain its form under rough usage and of the following internal dimensions:

Diameter 11.5 cm

Height 18.0 cm

PROCEDURE

The test sample: It consists of aggregates sized 12.5 mm - 10.0 mm(minimum 3kg).

The aggregates should be dried by heating at 100-110o C for a period of 4 hours and cooled.

1) Sieve the material through 12.5 mm and 10.0 mm IS sieve. The aggregates passing through 12.5 mm sieve and retained on 10.0 mm sieve comprises the test material.

2) The cylinder of the test shall be put in position on the base-plate and the test sample added in thirds, each third being subjected to 25 strokes with the tamping rod.

3) The surface of the aggregate shall be carefully levelled.

4) The plunger is inserted so that it rests horizontally on this surface, care being taken to ensure that the plunger does not jam in the cylinder

5) The apparatus, with the test sample and plunger in position, shall then be placed between the plates of the testing machine.

6) The load is applied at a uniform rate as possible so that the total load is reached in 10 minutes. The total load shall be 40 tonnes.

7) The load shall be released and the whole of the material is removed from the cylinder and sieved on 2.36mm IS Sieve.

8) The fraction passing the sieve shall be weighed and recorded.

REPORTING OF RESULTS

The mean of the two results shall be reported to the nearest whole number as the ‘aggregate crushing value’ of the size of the material tested.

RESULT

Aggregate Crushing test value = W2/W1 *100

![[PDF] Download IS 800 Code | Indian Standard Code for Steel](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjMmVdQd3q6sKYLbOG23DVJg2U_8IrdWJSfCcyA7gKs5NKVFBsi6dFPhGxoVctqzOHEIvJ6pqvQ6mpFMd5vV0U5IQHo-FETwRXTjbZ-Dok9CHxUJgePxHyFTHa2pNiWyW4mkYCJWOv_2IcP/w100/is-800-2007.JPG)

![[PDF] SP 16 :1980 Design Aids For Reinforced Concrete to IS : 456-1978](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEj3vWyWR9sVpY2Mcip5F3ttq_4jje6Et0mqiBug-q8n7kClvXle3KD0XtZBwYBtmYFfIekvQYIW9gFB5aqcri6KrHD4x2PalOyEWAXPkLNFfbXe8m9m8WvCLSEWok7vPivvYidB1tj8JjeX/w100/is-sp-16-1980.JPG)

![[PDF] IS 456 2000 | Download Civil Engineering Code](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjl8mzhZI_smGwhJPipCx2TuxHldgAvnHrYfkud8mDJ1kF4Syd83-TNKsXjyY1BVxFrxZ1tt-fErpupgiF146wqOfPtGo8M9GWrnQX9b9TyA-YtjlNWnlwdk9LaMN_JJN8AGCU619UI6Uu_/w100/is-456-2000.JPG)

0 Comments